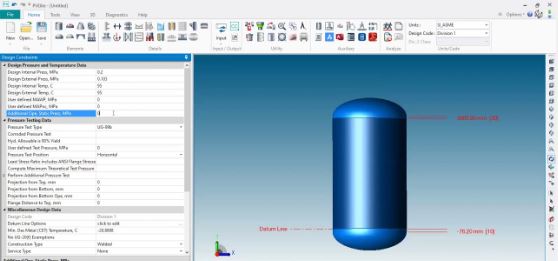

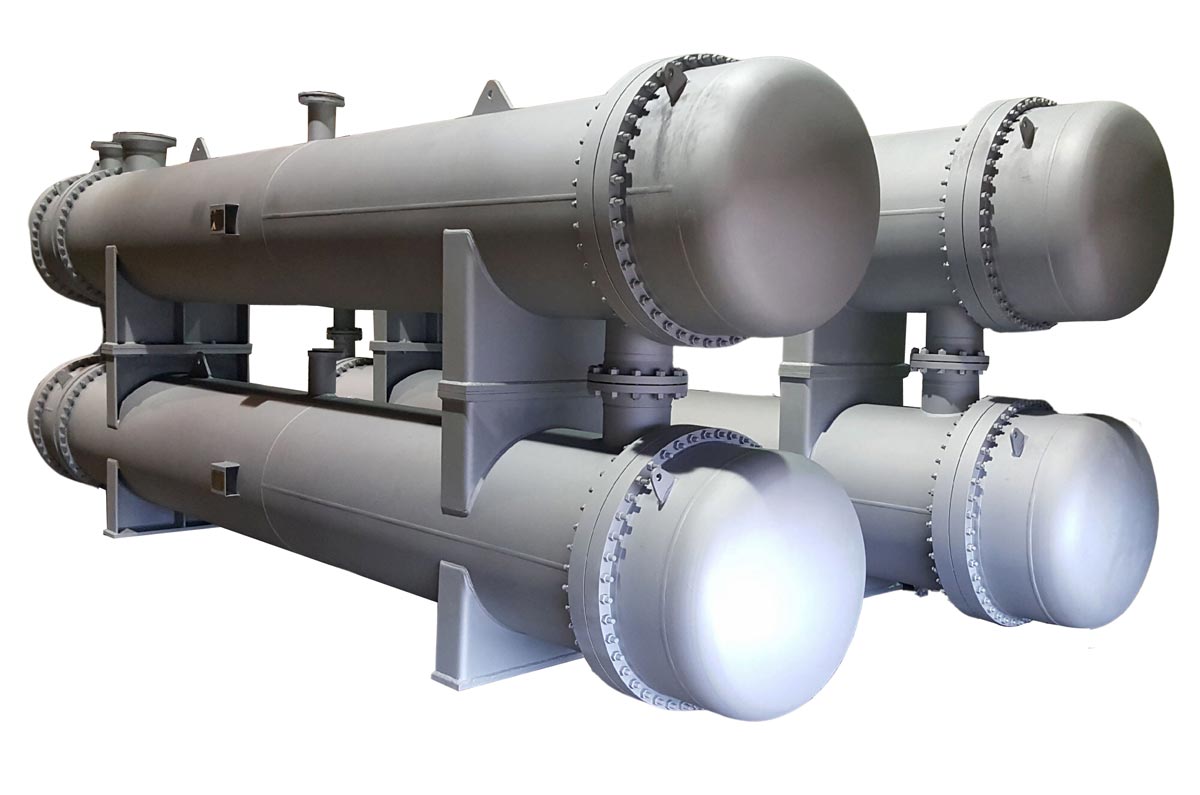

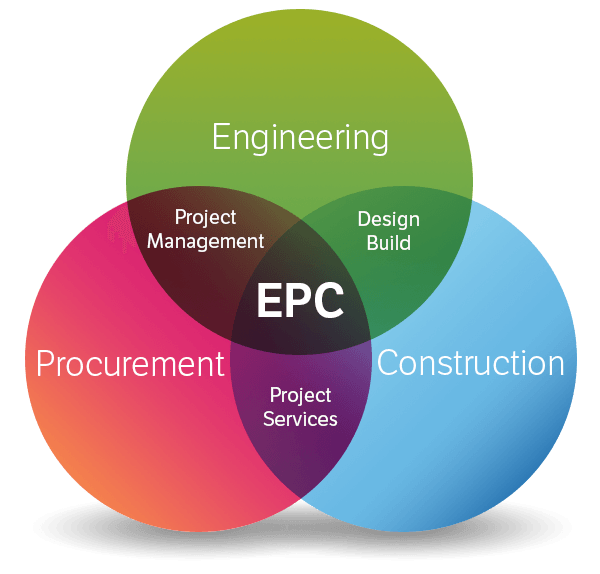

Heat Exchanger Design for Mechanical Static and Package Engineering Professionals

COMPLETED

Why enroll

Course details

Course suitable for

Training details

This is a live course that has a scheduled start date.

Live session

May 26, 2025 at 03:00 PM

2 Hours every day

10 Days

Our Alumni Work At

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

Petrofac

I was skeptical at first, but EveryEng's training programs really delivered. I gained the skills and confidence to take on challenging projects and advance my career. Highly recommended!

SLB

EveryEng stands out with its exceptional learning materials, expert guidance, and real-world applications. It can truly help to enhance skills and knowledge, making more confident professional.

SaiDeepa

I’m amazed by the depth of knowledge available on EveryEng. The platform covers various engineering topics in detail, making learning both exciting and rewarding. I would highly recommend it to everyone!

Servilink Systems

EveryEng offers a fantastic learning experience with a great selection of courses and expert mentors. The platform is user-friendly, and the knowledge gained is highly practical. It's been a great journey so far!

Halliburton

I had been looking for a reliable online platform for engineering courses, and EveryEng delivered beyond my expectations. The content is top-notch, the instructors are excellent, and the learning experience is seamless.

Questions and Answers

No questions yet - Be the first one to ask!