Preview this course

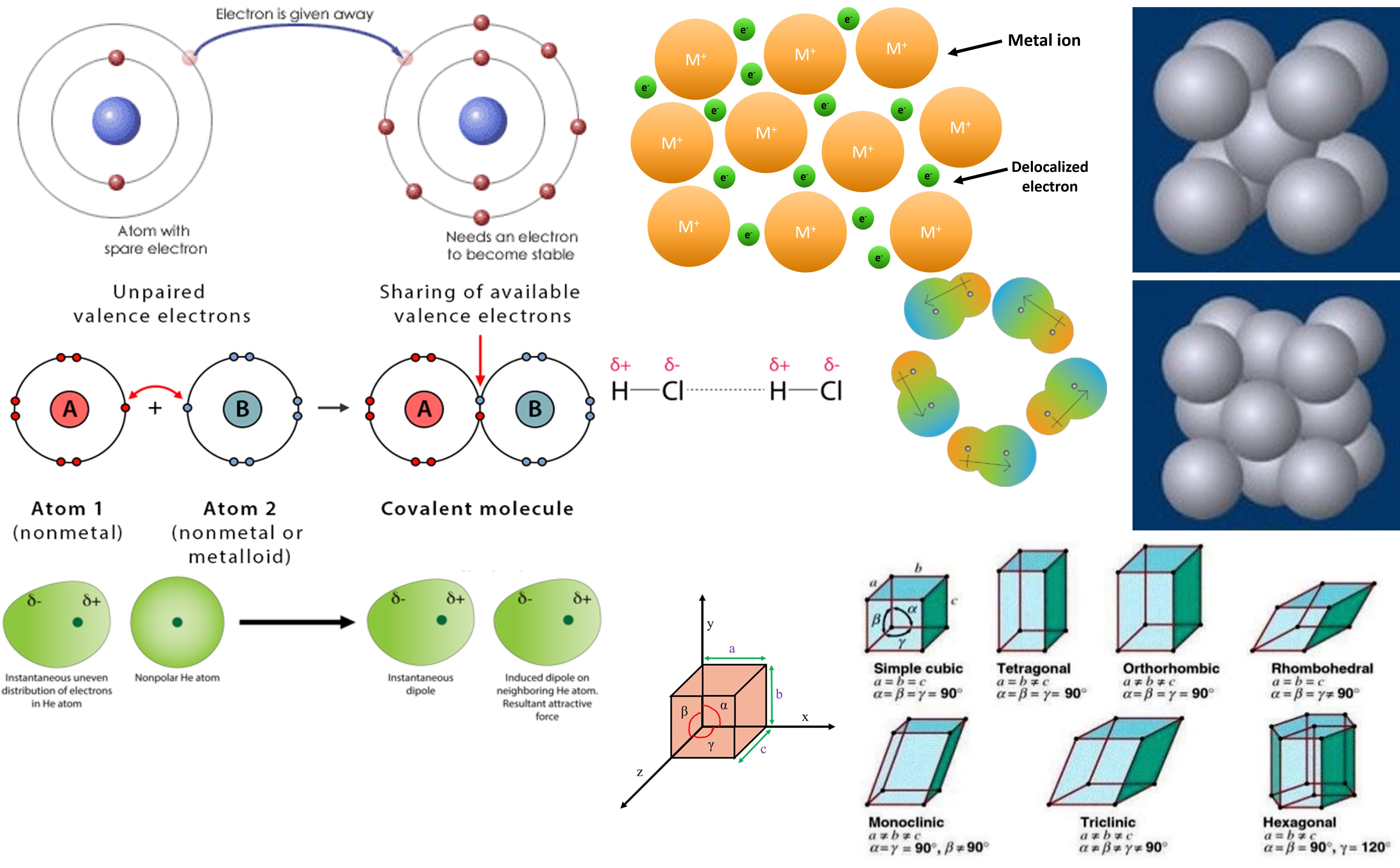

Introduction to Process Design Engineering

$ 70

Course content

The course is readily available, allowing learners to start and complete it at their own pace.

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

❮

❯