Heat Transfer_Crash Course for Campus Placement Interviews for Chemical Engineering

Team EveryEng

Mechanical Engineering

$ 25

Beginner course for learners

Heat Transfer_Crash Course for Campus Placement Interviews for Chemical Engineering

Trainers feedback

4

(42 reviews)

Team EveryEng

Mechanical Engineering

Course type

Instructor led live training

Course duration

10 Hrs

Course start date & time

Coming in Next Month

Language

English

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course?. Get in touch with our team if any clarification is required.

Why enroll

Heat up your career prospects with a crash course in Heat Transfer for Chemical Engineering campus placements! Mastering heat transfer concepts will make you a hot commodity in the job market, qualifying you for in-demand roles like Process Engineer, Thermal Systems Designer, or Energy Efficiency Specialist. With this expertise, you'll be sought after by top companies like BASF, 3M, or Siemens, and be equipped to drive innovation, optimize processes, and reduce energy costs. This crash course will give you the edge you need to land your dream job and ignite a successful career in chemical engineering!

Course details

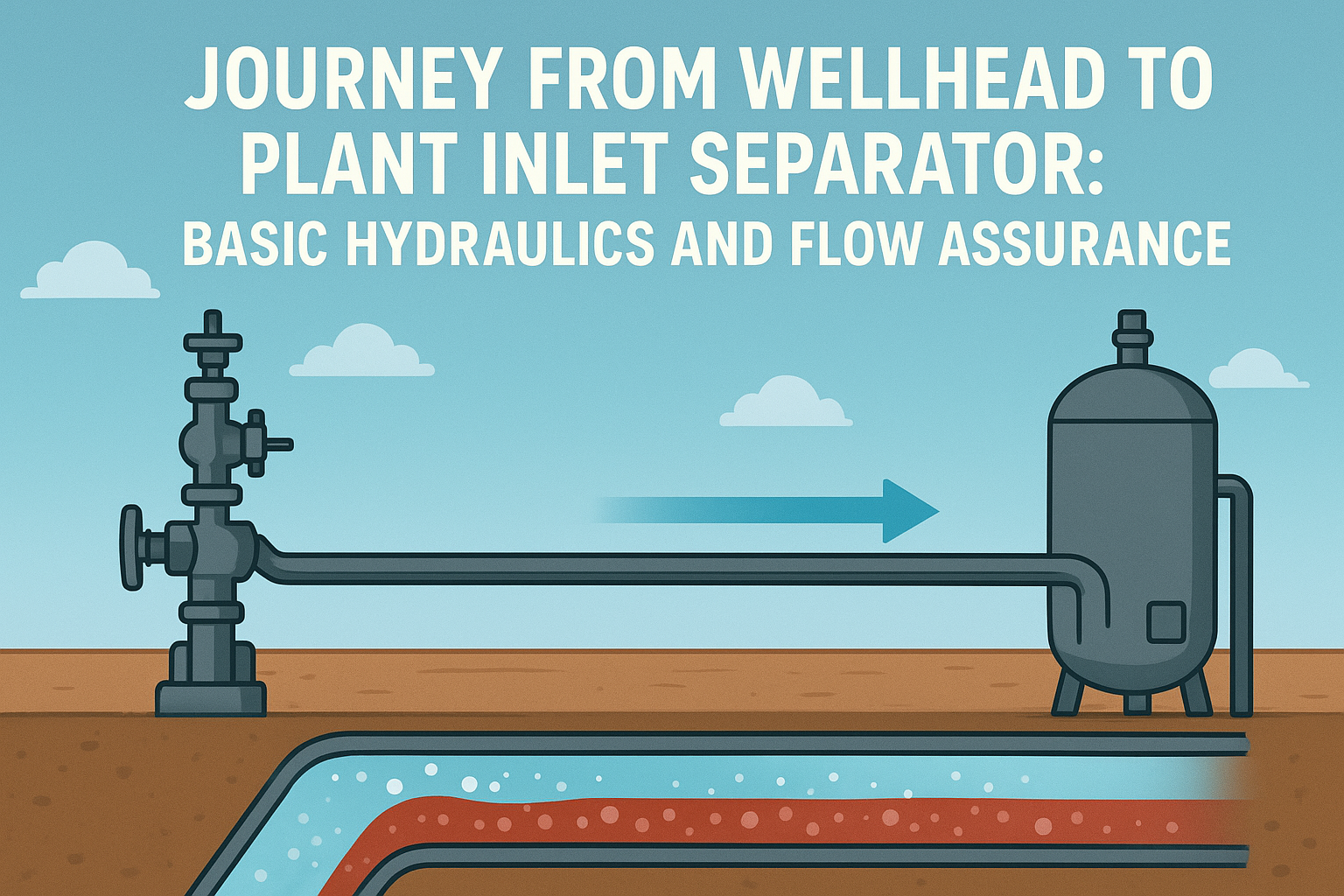

This crash course aims to help chemical engineering students prepare for campus placement interviews by providing a straightforward understanding of heat transfer operations. By the end of the module, students should be familiar with the basics of heat transfer, including conduction, convection, and radiation, as well as the principles behind heat exchangers and evaporators.

This course covers the fundamentals of heat transfer operations in a simplified manner. Students will learn about the different modes of heat transfer (conduction, convection, radiation) and their applications. Additionally, the course provides an overview of heat exchangers and evaporators commonly used in industrial processes. This crash course is designed to give students the confidence to discuss heat transfer topics during campus placement interviews.

Course suitable for

Oil & Gas Chemical & Pharmaceutical Energy & Utilities Chemical & Process Petroleum

Key topics covered

Training details

This is a live course that has a scheduled start date.

Live session

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

$ 25

- $ 0 Early bird discount

Coming in Next Month

Questions and Answers

A: Certainly! Heat transfer occurs in three primary modes: conduction, convection, and radiation. Conduction is the transfer of heat through a solid or stationary fluid by molecular activity, where energy is transferred from high to low temperature regions without bulk movement. For example, heat flowing through a metal rod. Convection involves heat transfer by the physical movement of a fluid (liquid or gas), where warmer regions of the fluid rise and cooler regions sink, facilitating heat exchange. This can be natural (due to buoyancy) or forced (using fans or pumps). Radiation is the transfer of heat through electromagnetic waves, primarily infrared, which does not require a medium and can occur in a vacuum, such as the heat from the sun reaching the earth. For more detailed reading, you can explore: https://en.wikipedia.org/wiki/Heat_transfer#Modes_of_heat_transfer.

A: Fourier's Law is a fundamental principle that describes the rate at which heat energy is conducted through a material. It states that the heat flux (the amount of heat transferred per unit area per unit time) is proportional to the negative gradient of the temperature and the thermal conductivity of the material. Mathematically: q = -k * (dT/dx), where q is heat flux, k is thermal conductivity, and dT/dx is the temperature gradient. This law is crucial as it forms the basis for solving steady-state and transient heat conduction problems in engineering. Understanding Fourier's Law enables engineers to predict heat flow in solids and design thermal systems effectively. More details can be found at: https://en.wikipedia.org/wiki/Fourier%27s_law.

A: The overall heat transfer coefficient (U) in a composite wall accounts for the combined resistances to heat flow from conduction through the wall layers and convection on the surfaces. It is calculated by taking the reciprocal of the sum of all thermal resistances in series. The resistances include conduction resistances (R_cond = thickness / (k * area)) for each layer and convective resistances (R_conv = 1 / (h * area)) on the surfaces. The formula is: 1/U = ΣR = 1/h_i + Σ(L_i/k_i) + 1/h_o, where h_i and h_o are inside and outside convective heat transfer coefficients, L_i and k_i are thickness and conductivity of each layer. The overall heat transfer coefficient helps determine the heat loss or gain through walls in insulation design and energy efficiency assessment. For a detailed example, see: https://www.engineeringtoolbox.com/overall-heat-transfer-coefficients-d_428.html.

A: Steady-state heat transfer occurs when the temperature field in the system does not change with time; that is, the amount of heat entering any part of the system equals the amount leaving, resulting in a constant temperature distribution. Transient (or unsteady-state) heat transfer happens when temperature varies with time, such as during heating or cooling processes until the system reaches equilibrium. Steady-state analysis is simpler and commonly used in design calculations where conditions are stable, while transient analysis is more complex and involves solving time-dependent differential equations, important in scenarios like thermal response of materials or start-up conditions. Reference: https://www.sciencedirect.com/topics/engineering/steady-and-unsteady-heat-transfer.

A: The Biot number (Bi) is a dimensionless parameter defined as the ratio of the internal thermal resistance within a body to the external convective thermal resistance at its surface: Bi = h * L_c / k, where h is the convective heat transfer coefficient, L_c is the characteristic length (typically volume/surface area), and k is the thermal conductivity. If Bi << 0.1, the temperature within the object can be assumed uniform (lumped system assumption), simplifying transient heat transfer analysis. However, if Bi > 0.1, spatial temperature gradients inside the body are significant, and more detailed methods like solving partial differential equations become necessary. Understanding Biot number helps in choosing appropriate modeling approaches. More info at: https://www.efunda.com/formulae/heat_transfer/dimensions/biot_number.cfm.

A: The Nusselt number (Nu) is a dimensionless number that represents the ratio of convective to conductive heat transfer across a boundary. It is defined as Nu = hL/k, where h is the convective heat transfer coefficient, L is characteristic length, and k is the fluid thermal conductivity. A higher Nusselt number indicates a more efficient convective heat transfer relative to conduction. It is essential in characterizing convective heat transfer in different flow regimes and geometries and is used in correlation equations to estimate the heat transfer coefficient. This helps in designing heat exchangers and predicting cooling/heating rates. For more details, check: https://en.wikipedia.org/wiki/Nusselt_number.

A: Thermal resistance is a measure of a material’s opposition to heat flow, analogous to electrical resistance but for heat transfer. It is defined as R = ΔT / Q, where ΔT is the temperature difference across the material and Q is the heat transfer rate. In heat exchanger design, thermal resistances from conduction through walls and convection on fluid surfaces are combined to model the overall heat transfer. By summing resistances in series or parallel, engineers can calculate the overall heat transfer coefficient and predict performance. Using thermal resistance simplifies complex heat transfer problems and aids optimization. For deeper insight, visit: https://www.thermopedia.com/content/111/.

A: The lumped capacitance method assumes that the temperature within a solid body is spatially uniform at any instant during transient heat transfer, implying negligible internal temperature gradients. The primary assumptions are: 1) Biot number (Bi) is less than 0.1, so internal conduction resistance is much smaller than surface convection resistance; 2) Material properties like density, specific heat, and conductivity are constant; 3) Heat transfer occurs primarily by convection on the surface; 4) There is no internal heat generation. These assumptions simplify transient heat transfer equations to ordinary differential equations, making analysis faster. Reference: https://www.engineeringtoolbox.com/lumped-heat-capacity-method-d_682.html.

A: Fins are extended surfaces attached to a primary surface to increase surface area for enhanced heat dissipation by convection. The extended area allows more heat to be transferred to the surrounding fluid without increasing the temperature gradient significantly. Fin efficiency depends on material thermal conductivity, fin geometry (length, thickness, shape), and the convective heat transfer coefficient. Longer fins may have lower efficiency due to temperature drop along the fin length. Fin effectiveness is the ratio of heat transfer with the fin to the heat transfer without it, used to evaluate performance. Detailed analysis involves solving fin equations (Fourier’s law with convection boundary conditions). For more insight: https://www.thermalfluidscentral.org/encyclopedia/index.php/Fins.

A: Laminar flow is characterized by smooth, orderly fluid motion where layers slide past each other with minimal mixing, typically at low Reynolds numbers (Re < 2300). Turbulent flow features chaotic fluctuations and mixing across layers, occurring at higher Reynolds numbers (Re > 4000). In forced convection, turbulent flow greatly increases heat transfer coefficients compared to laminar flow because the continuous mixing reduces the thermal boundary layer thickness, enhancing fluid contact with the surface. However, turbulence increases pressure drop and pumping power requirements. Engineers strive to optimize flow regime depending on system constraints. For a deeper understanding: https://www.thermalfluidscentral.org/encyclopedia/index.php/Laminar_and_Turbulent_Flows.

More from Same Author

- Technical Courses

- Articles

4 (42)

1333

36

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

4 (42)

683

11

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

4 (42)

887

17

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

5

1708

4

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

4 (20)

2022

10

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

4

2204

4

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

More Training & Development option to expand your reach

- Technical courses

- Soft-skills courses

- Seminars

- Articles & Blogs

4

175

Online

Live courses

December 21

1.5 Hrs

Beginner

Online

Live courses

Interacting with trainer

836

3

Online

Live courses

December 31

160 Hrs

Advanced

Online

Live courses

Interacting with trainer

92

Online

Live courses

January 8

9 Hrs

Beginner

Online

Live courses

Interacting with trainer