Introduction to CIM

Introduction to CIM - Part 2

Production System

Automation In Manufacturing System

Automation Principles and Computer Aided Technologies

Computer Graphics - 01

Computer Graphics - 02

Computer Graphics - 03

Computer Graphics - 04

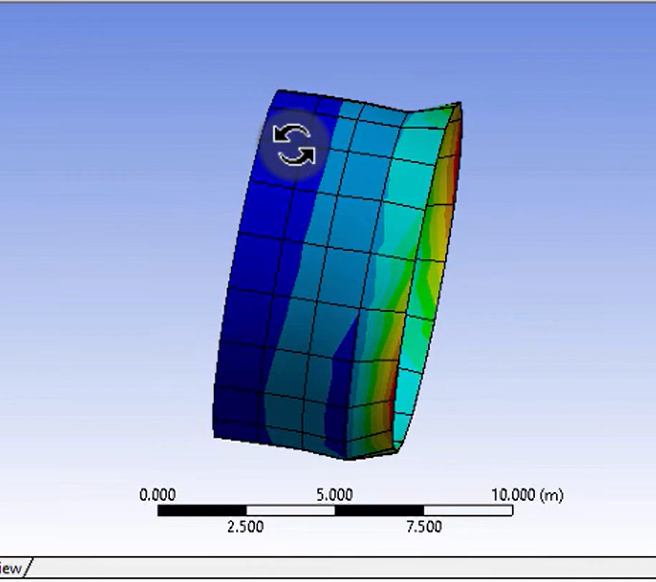

Geometric Modelling - 01

Geometric Modelling - 02

Computer Numerical Control - 01

Computer Numerical Control - 02

Computer Numerical Control - 03

Computer Numerical Control - 04

CNC Machining Center - 01

CNC Machining Center - 02

CNC Tooling

CNC Part Programming - 01

CNC Part Programming - 02

CNC Part Programming - 03

CNC Part Programming - 04

Laboratory Demonstration, Computer Aided Design -01

Laboratory Demonstration, Computer Aided Design -02

CAM Softwares

Laboratory Demonstration, CAM Softwares

Laboratory Demonstration, CNC Machining

Group Technology and Computer Aided Process Planning

Computer Aided Process Planning - 01

Computer Aided Process Planning - 02

Flexible Manufacturing System

Industrial Robotics

Programming Logical Controller

Automatic Identification and Data Capture

Computer Aided Quality Control

Computer Aided Quality Control - 02

Laboratory Demonstration Co-ordinate Measuring Machine

Rapid Manufacturing - 01

Rapid Manufacturing - 02

Laboratory Demonstration Rapid Manufacturing - 01

Laboratory Demonstration Rapid Manufacturing - 02

Laboratory Demonstration CAD using Fusion 360, an Introduction

Laboratory Demonstration CAD Using Fusion 360, Rendering and 3D printing

Material Handling and Identification

Laboratory Demonstration Plant Simulation Software - 01

Laboratory Demonstration Plant Simulation Software - 02

Laboratory Demonstration Plant Simulation Software - 03

Computers in Manufacturing Industry, current scenario - 01

Computers in Manufacturing Industry, current scenario - 02

Computers in Manufacturing Industry, current scenario - 03