Total Experience

11.5 Years

Current Company / College

Nikkiso Cosmodyne India Pvt Ltd.

City

vadodara

Country

India

Professional Experience

3 Years - piping stress engineer

Professional Career Summary

Performed piping stress analysis for Air Separation Plant systems using CAESAR II,

ensuring compliance with ASME B31.3 and relevant pressure-temperature ratings.Analyzed critical lines for thermal expansion, sustained, and occasional loads;

evaluated flange leakage risks using P-Equ and NC method, spring hanger calculation

and recommended corrective actions where required.Created detailed CAESAR II models of complete piping systems, associated

equipment (vessels, tanks, exchangers), and performed pump qualification as per API

610 allowable nozzle load criteria to ensure vendor compliance and safe operation.

• Recommended and implemented piping flexibility solutions, including:

• Addition of expansion loops

• Placement of restraints and guides

• Adjustment of routing to control displacement and loads.Collaborated with the team to incorporate stress findings into 3D piping layouts; also

generated stress isometrics from CAESAR II using ISOGEN for documentation and

fabrication purposes.Conducted nozzle load evaluations using vendor allowable and API/ASME criteria;

verified nozzle loads with NozzlePRO and ensured compliance for rotating and static

equipment.Performed stress analysis of vacuum jacketed (cryogenic) lines considering

temperature gradients, contraction effects, and support optimization for thermal

movement.Performed dynamic/modal analysis in CAESAR II to determine natural frequencies of

critical lines and ensure resonance avoidance near pump/compressor excitation

ranges.Prepared and submitted complete stress analysis reports, including stress summary,

restraint load report, displacement report, and flange leakage (NC method) report,

ensuring alignment with company ISO documentation standards.Designed and modeled skid-based piping systems using Autodesk Inventor, ensuring

manufacturability, maintainability, and space optimization.Created detailed fabrication and assembly drawings for piping and structural skids as

per project requirements.Interpreted P&ID drawings to extract pipe specifications, valve types, line classes, and

instrument connections for accurate 3D modeling and analysis.

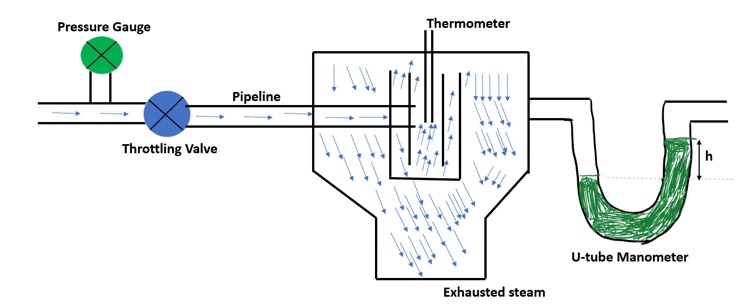

Courses From viren prajapati

Explore the books, articles, and research viren prajapati has authored or contributed to.