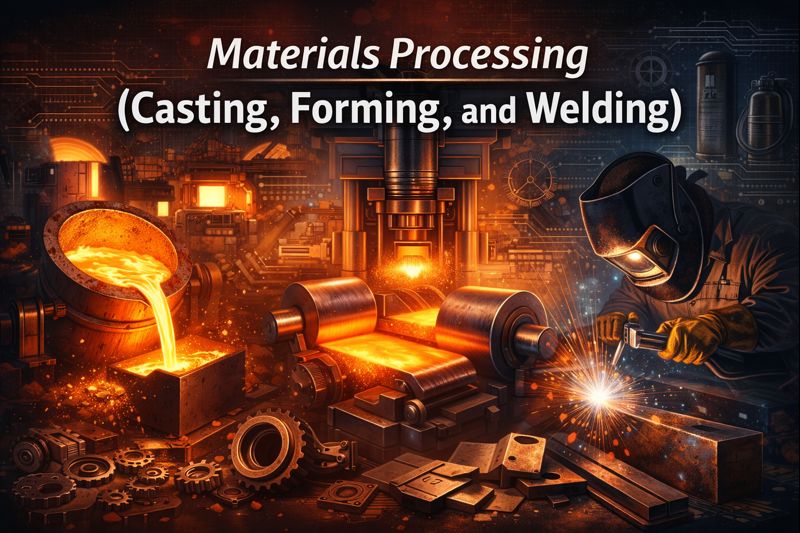

Materials Processing (Casting, Forming, and Welding) deals with the fundamental principles and practical techniques used to convert raw materials, particularly metals and alloys, into functional engineering components with desired shapes, dimensions, and properties. The course provides a comprehensive understanding of how material behavior, process parameters, and manufacturing conditions influence the quality, performance, and reliability of finished products.

The course begins with casting processes, focusing on the science of melting, pouring, solidification, and cooling of metals. Topics include sand casting, die casting, investment casting, and continuous casting, along with mold materials, gating and riser design, solidification defects, and methods for improving casting quality. Emphasis is placed on understanding microstructure evolution during solidification and its impact on mechanical properties.

Metal forming processes are then explored, covering both bulk deformation and sheet metal forming techniques such as rolling, forging, extrusion, drawing, bending, and deep drawing. The course examines material flow, stress–strain behavior, plastic deformation, forming loads, lubrication, and formability limits. Process design considerations, defect prevention, and the role of temperature in hot and cold working are also discussed.

The welding and joining section focuses on permanent joining processes used in manufacturing and fabrication. Various welding techniques, including arc welding, resistance welding, gas welding, and advanced welding processes, are introduced. Topics include weld metallurgy, heat-affected zones, residual stresses, welding defects, and quality inspection methods. The course highlights the relationship between welding parameters, joint design, and structural integrity.

Overall, the course integrates theoretical concepts with practical insights to help participants understand the selection, design, and optimization of casting, forming, and welding processes. It prepares learners to address real-world manufacturing challenges, improve product quality, and make informed decisions in materials processing and fabrication applications

source: NPTEL[youtube]