Physical Metallurgy - Learn about Iron (Fe) – Iron Carbide (Fe3C) Phase Diagrams

$ 20

Beginner course for learners

Physical Metallurgy - Learn about Iron (Fe) – Iron Carbide (Fe3C) Phase Diagrams

Trainers feedback

5

(3 reviews)

Course type

Instructor led live training

Course duration

2 Hrs

Course start date & time

Coming in Next Month

Language

English

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course?. Get in touch with our team if any clarification is required.

Why enroll

• Construction of Fe-Fe3C phase diagram.

• Understand the role of temperature in the Fe-Fe3C phase diagram and the formation of various phases in this 2-component system.

• Differentiate between different phases based on their structure and properties.

• Learn the fundamentals of eutectic, eutectoid, and peritectic reactions and their significance in Fe-Fe3C systems.

Course details

• Construction of Fe-Fe3C phase diagram.

• Understand the role of temperature in the Fe-Fe3C phase diagram and the formation of various phases in this 2-component system.

• Differentiate between different phases based on their structure and properties.

• Learn the fundamentals of eutectic, eutectoid, and peritectic reactions and their significance in Fe-Fe3C systems.

Course suitable for

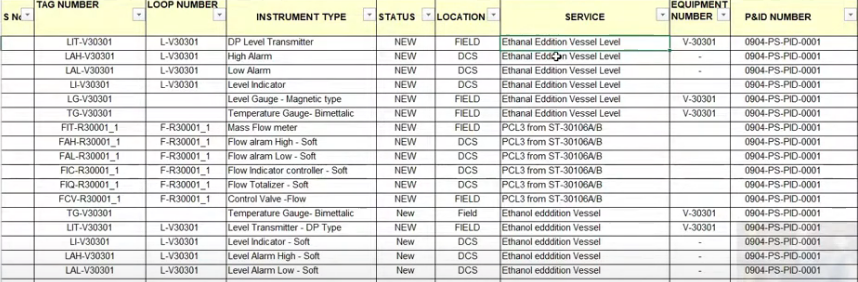

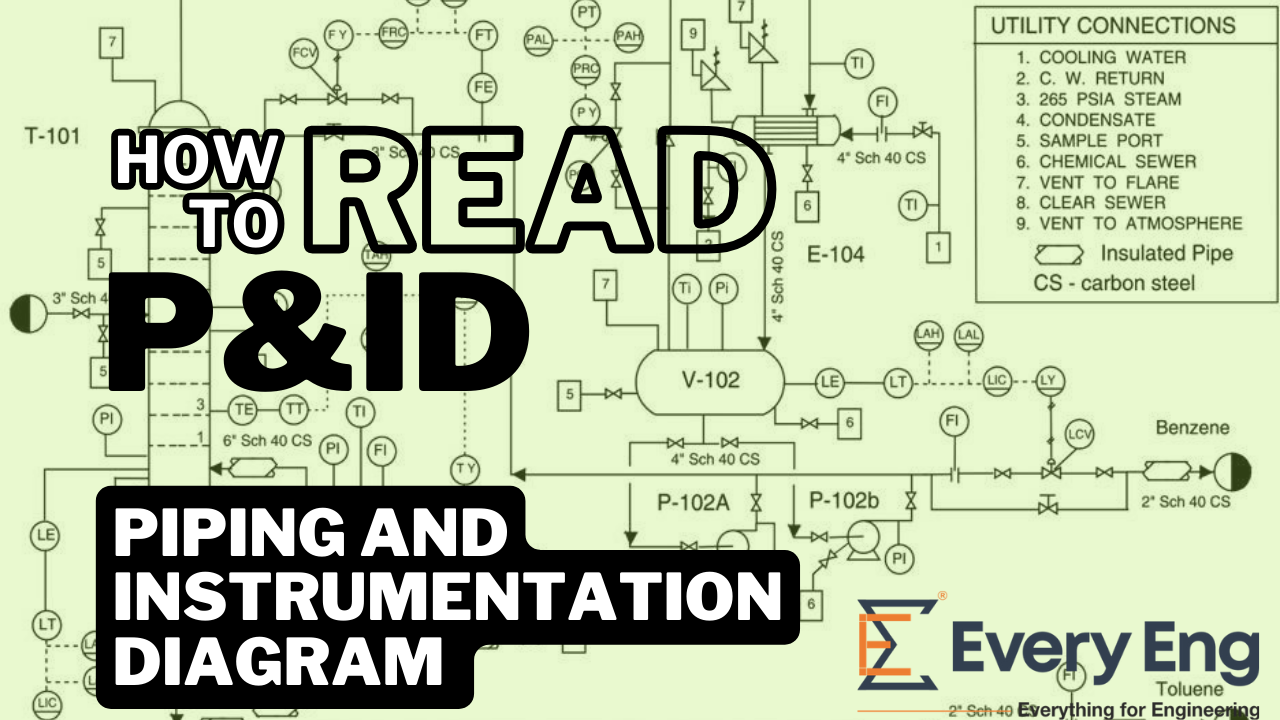

Chemical & Pharmaceutical Medical Instruments Chemical & Process Mechanical Metallurgy & Material Science

Key topics covered

Training details

This is a live course that has a scheduled start date.

Live session

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

$ 20

- $ 0 Early bird discount

Coming in Next Month

Questions and Answers

A: The Iron-Iron Carbide phase diagram represents the equilibrium phases and phase transformations in iron-carbon alloys up to about 6.67% carbon by weight. It is crucial for understanding the microstructures and properties of steel and cast iron. The diagram charts temperature versus carbon content and shows phases such as ferrite, austenite, cementite (Fe3C), pearlite, and others, illustrating their stability regions and transformations. For more detailed information, you can visit [Phase Diagrams for Iron-Carbon System](https://www.phase-trans.msm.cam.ac.uk/2008/Iron/Iron.html).

A: The key phases in the Iron-Fe3C phase diagram are: 1) Ferrite (α-Fe): a body-centered cubic (BCC) phase, soft and ductile, with very low carbon solubility. 2) Austenite (γ-Fe): a face-centered cubic (FCC) phase, stable at higher temperatures, with higher carbon solubility than ferrite. 3) Cementite (Fe3C): a hard, brittle intermetallic compound. 4) Pearlite: a lamellar mixture of ferrite and cementite formed by eutectoid transformation. 5) Ledeburite: a eutectic mixture of austenite and cementite occurring at very high carbon content. Understanding these phases helps in controlling steel microstructures for desired properties. Detailed explanation can be found in [ASM International Handbook, Volume 1](https://www.asminternational.org/).

A: In the Iron-Fe3C phase diagram, the eutectoid point occurs at approximately 0.76% carbon and 727°C, where austenite transforms into a lamellar mixture of ferrite and cementite called pearlite. A eutectic point occurs at 4.3% carbon and about 1147°C, where liquid transforms into austenite plus cementite (ledeburite). These points represent invariant reactions where phases transform simultaneously, playing a critical role in determining microstructure and mechanical properties of steels and cast irons. For more details, see [Phase Transformations in Metals and Alloys, D.A. Porter](https://books.google.com/books?id=Z6oLAAAAIAAJ).

A: Carbon content greatly influences steel properties. Low carbon steels (<0.2% C) are soft and ductile due to predominately ferrite phases. Medium carbon steels (0.2%-0.6% C) gain strength and hardness from pearlite formation. High carbon steels (>0.6% C) have increased cementite, making them very hard but brittle. The carbon content determines phase proportions and microstructures such as ferrite, pearlite, bainite, and martensite after heat treatment, directly controlling hardness, toughness, and ductility. For a practical overview, refer to [Steel Metallurgy Explained, The Balance](https://www.thebalance.com/basic-metallurgy-steel-2340490).

A: During slow cooling of austenite (γ-Fe) in the Iron-Fe3C diagram, the following transformations may occur depending on carbon content: At eutectoid composition (~0.76% C), austenite transforms to pearlite, a lamellar mixture of ferrite and cementite. For hypoeutectoid steels (<0.76% C), proeutectoid ferrite forms first, then the remaining austenite transforms to pearlite. For hypereutectoid steels (>0.76% C), proeutectoid cementite forms initially, followed by pearlite. These transformations influence the final microstructure and properties significantly. More details can be found in [Steel Heat Treatment Processes](https://www.totalmateria.com/page.aspx?ID=CheckArticle&site=ktn&NM=239).

A: The Iron-Fe3C phase diagram is fundamental for designing heat treatment processes such as annealing, normalizing, quenching, and tempering. It allows prediction of phases present at specific temperatures and carbon contents to manipulate microstructure and improve mechanical properties. For example, heating steel into the austenite region (γ phase) followed by controlled cooling influences formation of pearlite, bainite, or martensite. Understanding phase boundaries and transformations helps optimize process parameters for desired hardness, strength, and ductility. More information is available in [Heat Treatment of Steel - ASM International](https://www.asminternational.org/documents/10192/1849770/06782G_Chapter_07.pdf).

A: The eutectoid reaction at 0.76% carbon and 727°C is critical in steel metallurgy, where austenite (γ) transforms into pearlite – a fine lamellar mixture of ferrite (α) and cementite (Fe3C). This reaction governs the mechanical properties of medium carbon steels since pearlite provides an optimal balance of strength and ductility. The eutectoid transformation is also the basis for many heat treatment processes controlling grain size and phase distribution. For further reading, see [Introduction to Physical Metallurgy by Sidney H. Avner](https://www.amazon.com/Introduction-Physical-Metallurgy-Sidney-Avner/dp/0070610285).

A: Carbon solubility varies significantly between ferrite (α-Fe) and austenite (γ-Fe). Ferrite has a body-centered cubic (BCC) structure with very limited carbon solubility, typically up to 0.02 wt.% at 727°C. In contrast, austenite, with its face-centered cubic (FCC) structure, can dissolve significantly more carbon, up to about 2.1 wt.% at 1147°C. This greater solubility in austenite enables carbon to be more evenly distributed during heat treatment and plays a key role in phase transformations outlined by the phase diagram. Detailed explanation is available at [Materials Science and Engineering: An Introduction by Callister](https://www.wiley.com/en-us/Materials+Science+and+Engineering%3A+An+Introduction%2C+10th+Edition-p-9781119405498).

A: Pearlite is a distinctive microstructure found in steel, consisting of alternating layers (lamellae) of ferrite and cementite formed by the eutectoid transformation of austenite at 0.76% carbon and 727°C. It is mechanically important because it combines the ductility of ferrite with the hardness of cementite, resulting in balanced strength and toughness. Unlike bainite or martensite, pearlite forms during relatively slow cooling and has a characteristic lamellar appearance under a microscope. To learn more about pearlite, you can consult [Pearlite - Microstructure and Mechanical Properties](https://www.azom.com/article.aspx?ArticleID=8851).

More from Same Author

- Technical Courses

- Articles

5

1449

5

Online

Live courses

November 17

2 Hrs

Online

Live courses

Interacting with trainer

5

736

1

Online

Live courses

October 20

2 Hrs

Online

Live courses

Interacting with trainer

961

Online

Live courses

March 8

15 Hrs

Online

Live courses

Interacting with trainer

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

5

731

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

4 (21)

1020

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

4

2548

10

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

More Training & Development option to expand your reach

- Technical courses

- Soft-skills courses

- Seminars

- Articles & Blogs

4

175

Online

Live courses

December 21

1.5 Hrs

Beginner

Online

Live courses

Interacting with trainer

836

3

Online

Live courses

December 31

160 Hrs

Advanced

Online

Live courses

Interacting with trainer

92

Online

Live courses

January 8

9 Hrs

Beginner

Online

Live courses

Interacting with trainer