Metrology- Mechanical Engineering

FREE

19 already enrolled!

Why enroll

Course content

The course is readily available, allowing learners to start and complete it at their own pace.

Course details

Course suitable for

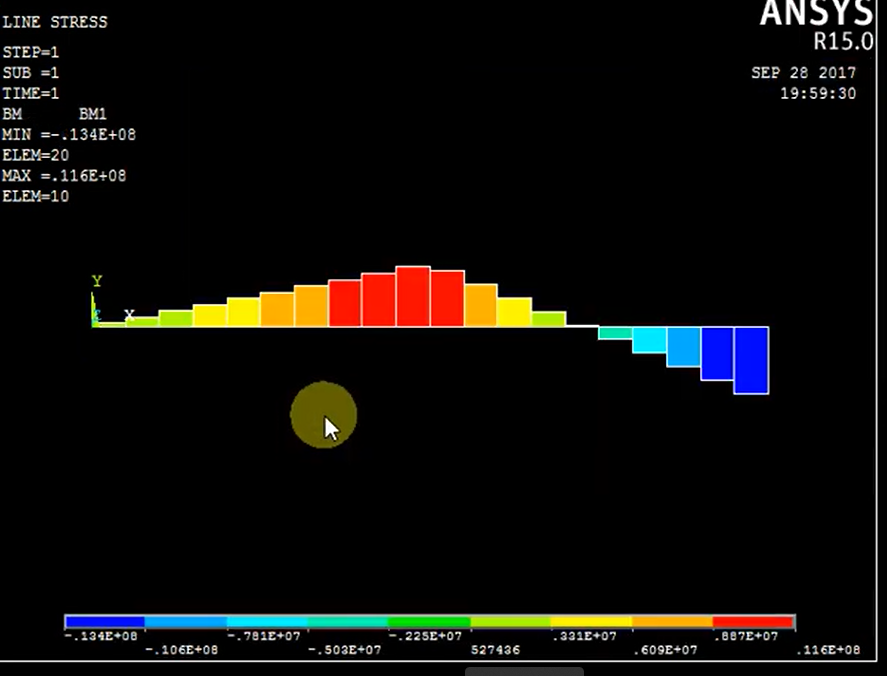

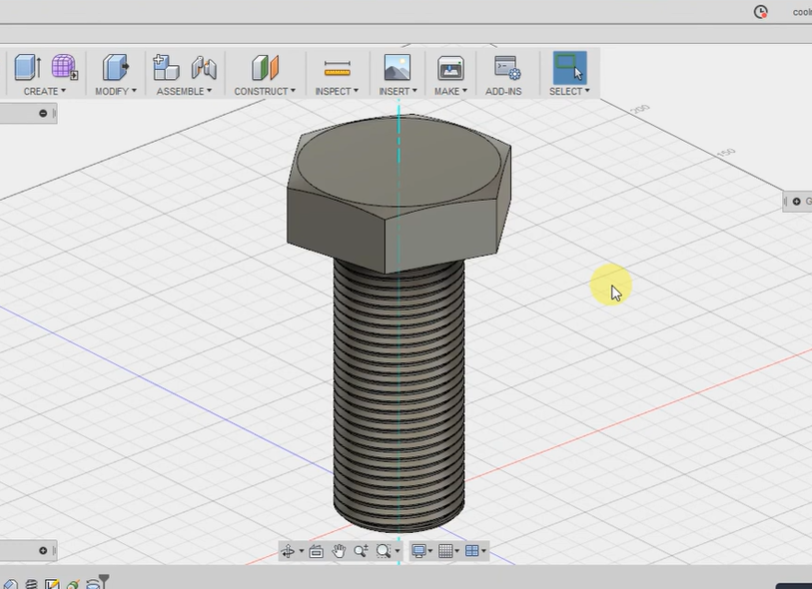

Key topics covered

Our Alumni Work At

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

Petrofac

I was skeptical at first, but EveryEng's training programs really delivered. I gained the skills and confidence to take on challenging projects and advance my career. Highly recommended!

ITER

The user experience on EveryEng is fantastic! The platform is simple, efficient, and provides excellent educational content. It helps developing new skills and gain confidence in engineering career.

Subsea7

I was searching for a reliable platform to expand my engineering knowledge, and EveryEng exceeded my expectations. The content and courses are well-structured, informative, and taught by experienced professionals. A great platform for Engineers!

Technip

The content quality on EveryEng is outstanding! Every lesson is well-organized, and the instructors explain everything so clearly. This platform can help every engineer grow professionally in ways I never imagined.

SLB

I never imagined an online learning platform could be this effective! EveryEng’s courses are top-notch, the mentors are industry experts, and the skills my team gained have made a real difference in the performance!"

Questions and Answers

No questions yet - Be the first one to ask!