Essential course for, Field Engineers, Supervisors, Drilling Engineers, and Other Upstream Professionals

This course aims to provide upstream professionals with advanced knowledge of mud engineering, focusing on wellbore stability, mud testing, reservoir drill-in fluids, and the interdisciplinary optimization of drilling fluids. Participants will gain practical insights into how drilling fluids contribute to safer, more efficient, and cost-effective drilling operations.

Course Duration: 15 hr

Course Overview:

1. Introduction to Mud Engineering & Key Functions

Overview of Drilling Fluids: Types and Composition

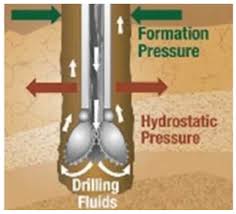

Critical Functions of Drilling Fluids:

o Wellbore Stability

o Cuttings Transport

o Lubrication and Cooling of the Drill Bit

o Formation Pressure Control

o Minimizing Formation Damage

Emphasis on Efficiency Gains in Drilling Operations

2. Understanding Wellbore Instability and Mitigation Strategies

Types of Wellbore Instability:

o Mechanical Instability: Causes and Indicators

o Chemical Instability: Mechanisms and Triggers

Mitigation Techniques:

o Optimizing Mud Weight and Rheology

o Chemical Treatments to Stabilize Shales and Other Reactive Formations

o Real-Time Monitoring and Adaptive Techniques

3. Mechanical and Chemical Instability of the Hole

Mechanical Instability:

o Rock Mechanics and Stress Analysis

o Borehole Breakout and Collapse Prevention

o Casing Design and Drilling Practices to Enhance Stability

Chemical Instability:

o Interaction of Drilling Fluids with Formations

o Use of Inhibitors and Specialized Additives

o Managing Swelling and Dispersion of Reactive Clays

4. Mud Testing & Reservoir Drill-In Fluids (RDF)

Mud Testing Techniques:

o Key Laboratory and Field Tests: Density, Viscosity, Filtration, pH, etc.

o Practical Demonstrations and Hands-on Testing (if possible)

Reservoir Drill-In Fluids:

o Introduction and Key Differences from Regular Drilling Fluids

o Importance in Minimizing Formation Damage

o Selection Criteria for RDFs based on Reservoir Characteristics

o Bridging Agents and Their Role in Protecting the Formation

5. Protecting the Reservoir from Drilling-Induced Damage

Damage Mechanisms:

o Physical, Chemical, and Biological Factors Affecting Reservoir Rock

o The Role of Drilling Fluids in Formation Damage

Best Practices to Minimize Damage:

o Mud Formulation Techniques

o Clean-Up and Displacement Procedures

o Case Studies of Successful Damage Mitigation

6. Interdisciplinary Performance & Drilling Fluid Optimization

Cross-Disciplinary Collaboration:

o Working with Geologists, Reservoir Engineers, and Production Teams

o Aligning Drilling Fluid Performance with Overall Well Objectives

Fluid Optimization Strategies:

o Balancing Cost, Performance, and Environmental Impact

o Continuous Monitoring and Adjustments During Drilling

o Case Studies: Successful Optimizations in Complex Wells