Work System Design is a fundamental course in industrial and production engineering that focuses on the systematic design, analysis, and improvement of work systems to achieve high productivity, efficiency, safety, and worker well-being. The course integrates principles of ergonomics, work study, human factors, and operations management to develop optimized methods for performing tasks in manufacturing and service environments.

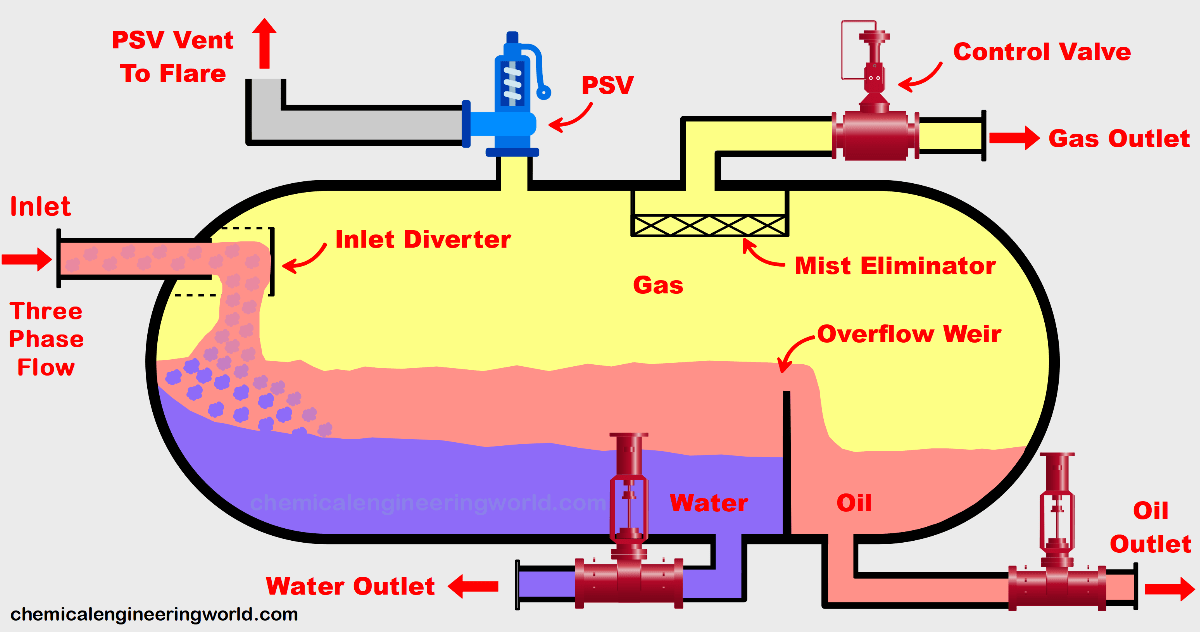

The course begins with an introduction to work systems and their components, including workers, machines, materials, methods, and the working environment. It emphasizes the importance of understanding human capabilities and limitations in designing effective work systems. Concepts such as anthropometry, biomechanics, physiological factors, and workplace ergonomics are covered to ensure safe, comfortable, and efficient job design.

Key topics include method study, work measurement, time study, standard time determination, and productivity analysis. Students learn to analyze existing work methods, eliminate unnecessary motions, and develop improved processes using tools such as process charts, motion study, and principles of motion economy. The course also addresses job design, work layout planning, and material handling systems to enhance workflow and reduce fatigue and delays.

In addition, Work System Design covers workplace safety, environmental factors, and quality of work life, highlighting their impact on employee performance and organizational effectiveness. Modern approaches such as lean manufacturing, work system optimization, and the use of digital tools for work analysis are introduced to align the course with current industrial practices.

By the end of the course, learners gain the skills required to design and evaluate efficient, safe, and human-centered work systems. The knowledge acquired is highly relevant for careers in manufacturing, operations management, ergonomics, industrial engineering, and productivity improvement initiatives.

source : NPTEL [youtube]