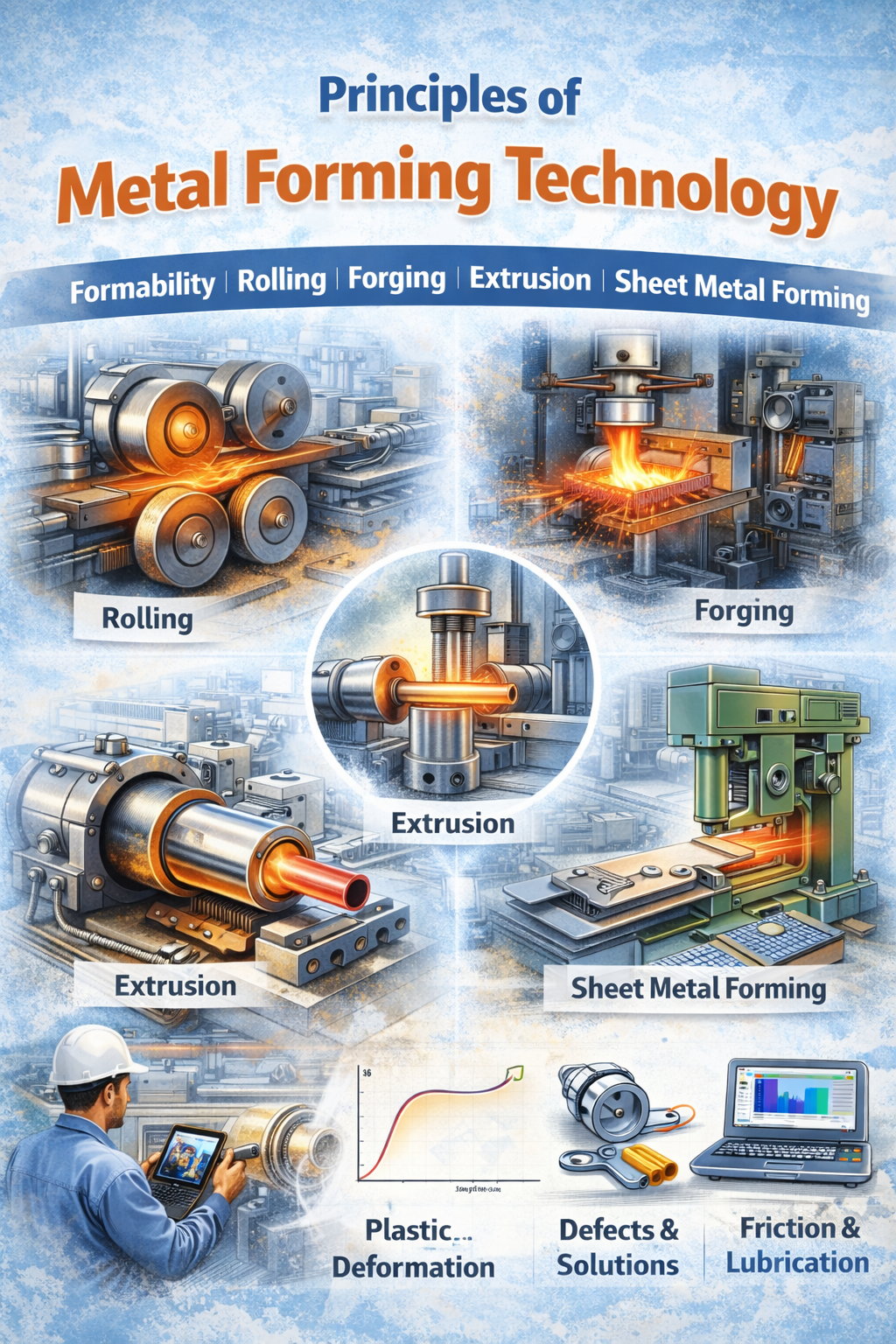

Principles of Metal Forming Technology is a core manufacturing engineering course that focuses on the science and engineering principles involved in shaping metals through plastic deformation. The course provides a comprehensive understanding of how metals behave under applied stresses beyond their elastic limit and how this behavior is utilized in industrial forming processes to produce components with desired shapes, dimensions, and mechanical properties.

The course begins with an introduction to the fundamentals of plastic deformation, including stress–strain behavior, yield criteria, flow rules, strain hardening, and the effects of temperature and strain rate on metal flow. Concepts of metal flow, formability, and workability are explained to help students understand the limits and capabilities of different materials during forming operations.

Various metal forming processes are studied in detail, including rolling, forging, extrusion, drawing, and sheet metal forming operations such as bending, deep drawing, and stretch forming. The working principles, process parameters, tooling, and equipment used in each process are discussed along with advantages, limitations, and typical industrial applications. The course also introduces defects in metal forming, such as cracking, wrinkling, and residual stresses, and methods for their prevention and control.

In addition, the course covers analytical and empirical approaches to metal forming analysis, including force and power requirements, friction and lubrication, and basic process modeling. Modern developments such as computer-aided metal forming, finite element analysis, and advanced forming techniques are introduced to provide exposure to current industrial practices.

By the end of the course, learners gain a strong theoretical foundation and practical insight into metal forming technologies, enabling them to analyze forming processes, select appropriate methods and materials, and contribute effectively to manufacturing process design, optimization, and quality improvement in metalworking industries.

source : NPTEL[youtube]