Design of Pressure Vessel using COMPRESS – Different Load Cases

Shanmugam V

Lead / Senior Mechanical Engineer/Static Equipment Engineer

$ 50

Beginner course for learners

Foundational Learning

Access to Study Materials

Self-Paced Learning

Design of Pressure Vessel using COMPRESS – Different Load Cases

Course type

Instructor led live training

Course duration

3 Hrs

Course start date & time

Coming in Next Month

Language

English

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course?. Get in touch with our team if any clarification is required.

Why enroll

1. How elementary and advanced topics of Solid mechanics are applied in development of Pressure vessel codes and standards.

2. Theoretical background behind design code requirements which helps an engineer understand the strengths, weaknesses and applicability of the code requirements.

3. An insight into the newly introduced codes.

4. Bridging the gap between theoretical knowledge and code requirements.

5. University students who want to take up career in static equipment engineering and wants to learn about the most widely used Industrial standard.

6. Experienced engineers who want to understand the background of code rules and requirements

Opportunities that awaits you!

Earn a course completion certificate

Add this credential to your LinkedIn profile, resume, or CV. Share it on social media and in your performance review

Course details

This course will cover basic and advanced topics of Pressure Vessel Engineering Design and Manufacturing requirement to provide a robust understanding of the background theory behind technical requirements of Pressure Vessel codes and standards. This will serve as a refresher course on core and advanced topics of Pressure Vessel Engineering to understand technical background of design and analysis as per codes & standards.

This course covers all important aspects of Pressure Vessel Design, Fabrication and testing, which comprises of

• Design, Analysis and Engineering requirement for Pressure Vessel

• Metallurgy and Material Selection while designing Pressure vessel

• Fabrication prerequisite while Pressure Vessel engineering

• Heat Treatment requirement for Pressure Vessel

• Testing & Inspection essentials for Pressure Vessel Design

All of above topics are covered in different modules of this course hence we encourage you to enroll all modules to learn all major and critical areas of Pressure vessel engineering.

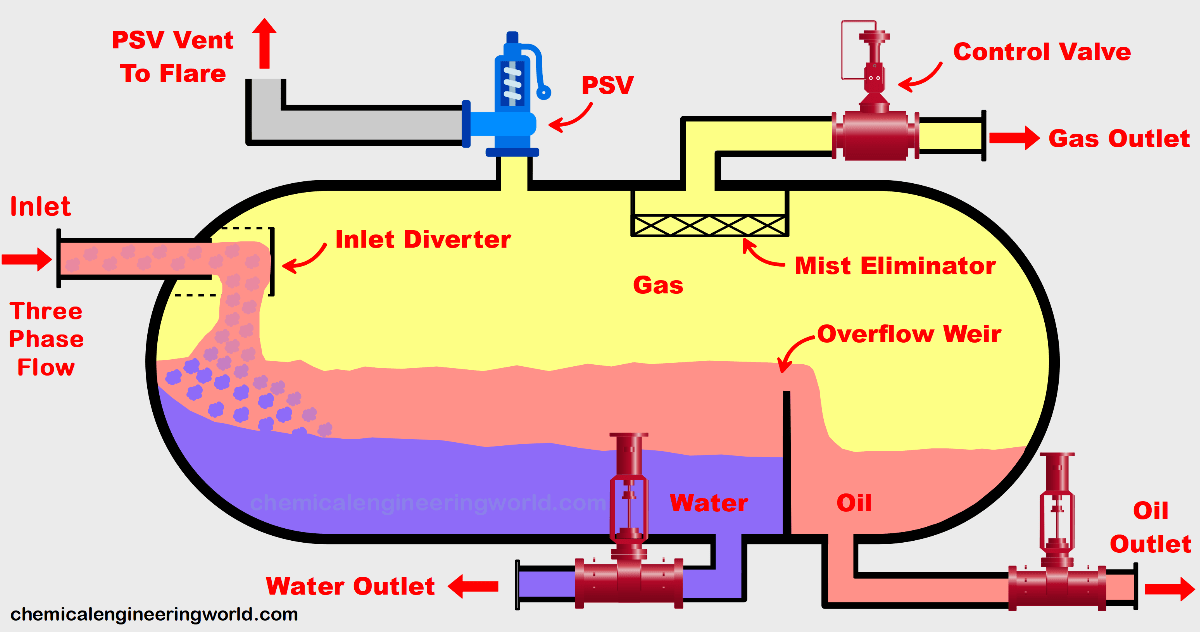

Classifications of Static Equipment Engineering is a specialized discipline of Mechanical Engineering which covers the design of static equipments like Pressure vessels (Process Columns, Drums, Reactors, Separators, Drain vessel), Heat exchangers (Shell and Tube, Plate and Frame, Plate and Shell, Air Coolers), Atmospheric Tanks (Low pressure and LPG Tanks), Flare Stack in chemical, petrochemical, or hydrocarbon facilities. We have different courses to cover above listed equipment & do participate in all courses.

Course suitable for

Oil & Gas Pharmaceutical & Healthcare Energy & Utilities Mechanical

Key topics covered

- This module talks about fundamentals of Pressure vessel Design & Engineering. Following topics are covered in this module

1. Understand Different Load Cases & it’s impact

a. Different types of internal and external loads

b. Wind loads

c. Seismic loads

d. Snow loads

e. Impact Loads

f. Transportation loads

g. Erection loads

Do enroll other module to learn more on fundamentals of Design of pressure vessel and understand ASME Code that are critical for a static equipment engineer.

Training details

This is a live course that has a scheduled start date.

Live session

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

$ 50

- $ 0 Early bird discount

Coming in Next Month

Questions and Answers

A: Seismic loads are incorporated in COMPRESS by defining acceleration values (typically peak ground accelerations) in the horizontal and vertical directions, along with the mass properties of the vessel and contents. These inputs generate inertial forces that simulate earthquake effects on the vessel structure. COMPRESS applies these forces as load cases and combines them with other loads such as pressure and weight as per seismic design guidelines specified in codes like ASME or local regulations. The software then evaluates stress intensities and stability under seismic conditions to ensure design adequacy.

A: Yes, COMPRESS can effectively design pressure vessels under external pressure loads. External pressure can cause buckling or collapse, which is different from internal pressure stress considerations. COMPRESS performs stability analysis to ensure that the vessel walls and components have adequate thickness and strength to resist buckling under vacuum or external pressure conditions. It follows the guidelines in ASME Section VIII, Division 2, or AD 2000 depending on user choice. Users input the external pressure conditions, and the software provides safety factors and checks to comply with the relevant codes.

A: Common mistakes include: incorrect input of load magnitudes or directions, neglecting to consider combined load scenarios, not specifying temperature effects properly, overlooking occasional or environmental loads like wind or seismic, and misuse of load case combinations contrary to code requirements. Additionally, not properly defining support conditions or ignoring weight of nozzles and attachments can lead to inaccurate results. To avoid these pitfalls, careful reading of the code and thorough training on COMPRESS software is recommended. Hexagon offers comprehensive tutorials and webinars covering these topics.

A: COMPRESS allows the user to define multiple load cases separately, such as internal pressure, weight loads, wind, seismic, and thermal loads. Each load case is analyzed individually for stresses and deformations. The software then can combine these load cases according to relevant design codes (e.g., ASME Section VIII Div.1 or Div.2) to evaluate the overall stress conditions. This combined stress assessment helps ensure that the vessel design meets safety and regulatory requirements under all possible operating scenarios. More on load combinations can be found at ASME code references and Hexagon's training materials.

A: Typical load cases include: internal pressure, external pressure (vacuum or hydrostatic pressure), weight of the vessel and contents (including supports), wind load, seismic (earthquake) load, thermal expansion or gradients, and occasionally occasional loads such as impact or operational loads like water hammer. Each of these load cases affects the vessel in different ways and must be analyzed either individually or in combination to comply with code requirements. COMPRESS facilitates this by allowing the definition and combination of these loads for a comprehensive structural analysis.

A: In COMPRESS, factors of safety are embedded within the code-based design criteria. Each load case or combination is evaluated against allowable stresses, which inherently include safety margins as specified by the design code (e.g., ASME Section VIII defines permissible stress limits with safety factors incorporated). The software calculates stress intensities and checks if they fall below allowable levels under all load cases and combinations, effectively applying safety factors during validation without manual input from the user. Users can view utilization ratios or margins of safety within COMPRESS reports for confidence in their design.

A: In COMPRESS, thermal loads are input by specifying temperature gradients or uniform temperature changes over the vessel's components. These temperature inputs generate thermal stresses due to expansion or contraction, which are considered alongside mechanical loads like pressure and weight. Typically, you enter the operating and ambient temperatures, or temperature differentials where applicable. The software then calculates the resulting thermal stresses and combines them with other load case stresses during the design verification. For an in-depth tutorial, see: https://hexagonppm.com/resources/webinars/thermal-stress-analysis

A: The first step is to define the geometry of the pressure vessel accurately in COMPRESS. This includes specifying dimensions such as diameter, length, thickness, and any nozzles or openings. After defining the geometry, you input the material properties. Once the vessel is modeled, you then set up different load cases, such as internal pressure, external pressure, wind load, seismic load, and thermal stresses. It is crucial to consider combined loading scenarios to ensure the vessel's integrity under real operating conditions. For detailed guidance, the COMPRESS user manual and Hexagon's official documentation provide step-by-step procedures: https://hexagonppm.com/products/pressure-vessel-design-software/COMPRESS

A: COMPRESS supports multiple widely recognized pressure vessel design codes including ASME Section VIII Division 1 & 2, PD 5500 (British code), EN 13445 (European code), and AD 2000 (German code). These codes govern how load cases should be considered, how stresses are calculated, safety factors, and acceptance criteria for pressure vessels. The software tailors its analysis and reporting according to the selected code to ensure compliance with national and international regulations. For complete details on code support, see: https://hexagonppm.com/products/pressure-vessel-design-software/COMPRESS/codes

A: Load case combinations in COMPRESS are managed using predefined or user-defined combination rules that follow relevant design codes. For pressure vessel design, codes like ASME Section VIII specify how different loads should be combined—for example, combining pressure with occasional loads like wind or seismic events. COMPRESS allows the user to select or create these combination cases, after which the software analyzes the combined stresses to verify the vessel's strength and stability. This ensures that the design is safe under all realistic operational scenarios. The documentation on load combinations is available within the software's help section and Hexagon's learning resources.

More from Same Author

- Technical Courses

- Articles

2865

Online

Live courses

Beginner

Online

Live courses

Interacting with trainer

1108

Online

Live courses

Beginner

Online

Live courses

Interacting with trainer

577

Online

Live courses

Beginner

Online

Live courses

Interacting with trainer

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

4

4874

47

E-Learning

Unlimited access

Beginner

E-Learning

Unlimited access

Pre-recorded videos

2929

22

E-Learning

Unlimited access

Advanced

E-Learning

Unlimited access

Pre-recorded videos

2438

4

E-Learning

Unlimited access

Beginner

E-Learning

Unlimited access

Pre-recorded videos

More Training & Development option to expand your reach

- Technical courses

- Soft-skills courses

- Seminars

- Articles & Blogs

1711

6

Online

Live courses

December 31

160 Hrs

Advanced

Online

Live courses

Interacting with trainer

689

Online

Live courses

February 21

30 Hrs

Advanced

Online

Live courses

Interacting with trainer

4

256

1

Online

Live courses

February 28

2 Hrs

Beginner

Online

Live courses

Interacting with trainer