Unit Operations - Basic to Advance

FREE

21 already enrolled!

Beginner course for learners

Foundational Learning

Access to Study Materials

Self-Paced Learning

Unit Operations - Basic to Advance

Trainers feedback

5

(1 reviews)

Course type

Watch to learn anytime

Course duration

240 Min

Course start date & time

Access anytime

Language

English

This course format through pre-recorded video. You can buy and watch it to learn at any time.

Opportunities that awaits you!

Earn a course completion certificate

Add this credential to your LinkedIn profile, resume, or CV. Share it on social media and in your performance review

Course content

The course is readily available, allowing learners to start and complete it at their own pace.

Unit Operations - Basic to Advance

2 Lectures

240 min

Unit Operations-1

Preview

144 min

Unit Operations-2

96 min

Course details

To equip participants with a thorough understanding of unit operations, covering fundamental concepts to advanced techniques, enabling them to design, analyze, and optimize various industrial processes.

Dive into the core principles of unit operations, explore key processes such as distillation, filtration, heat exchange, and fluid flow, and learn advanced methods for process optimization and troubleshooting through practical examples and case studies.

Course suitable for

Oil & Gas Pharmaceutical & Healthcare Energy & Utilities Chemical & Process Onshore Pipeline Petroleum

Key topics covered

Introduction to Unit Operations

Definition and significance in industrial processes

Overview of various unit operations

Fluid Mechanics

Fluid properties and behavior

Flow in pipes and channels

Pumps, compressors, and fluid movers

Heat Transfer

Conduction, convection, and radiation

Heat exchangers: types, design, and operation

Evaporation and condensation

Mass Transfer

Principles of diffusion and mass transfer

Distillation: methods and equipment

Absorption and stripping

Extraction: liquid-liquid and solid-liquid

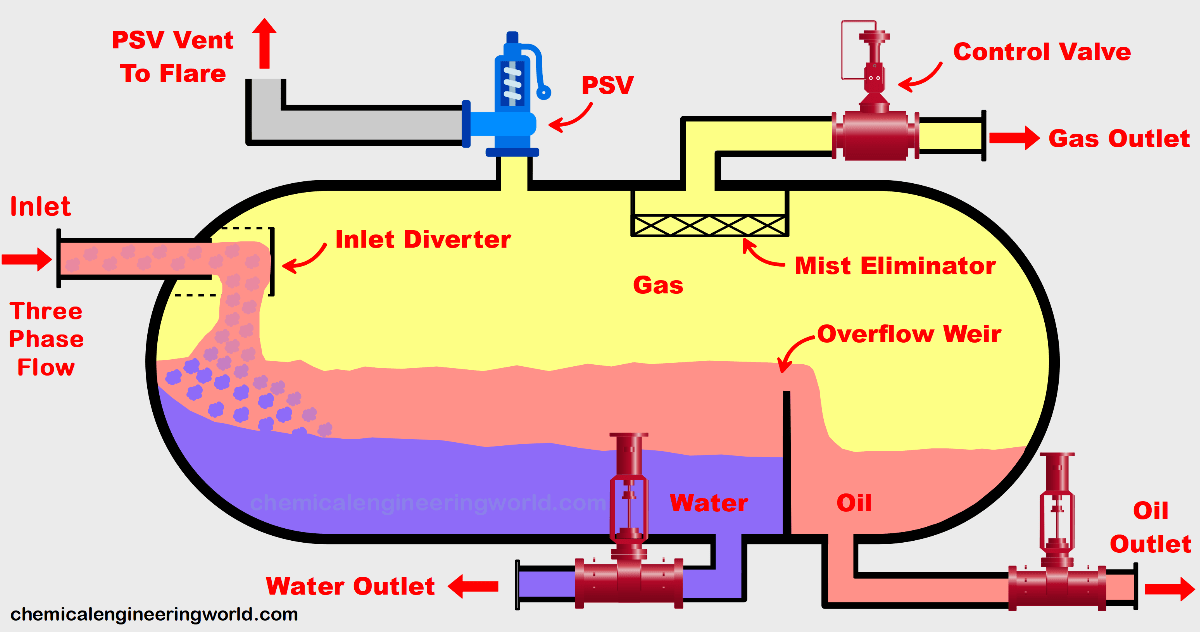

Mechanical Separations

Filtration: theory and equipment

Centrifugation

Sieving and screening

Chemical Reactors

Types of reactors: batch, continuous, and semi-batch

Reactor design and operation

Reaction kinetics and reactor sizing

Mixing and Agitation

Types of mixers and agitators

Mixing principles and scale-up

Applications in various industries

Crystallization and Solid-Liquid Separation

Principles of crystallization

Crystallizer design and operation

Solid-liquid separation techniques

Drying

Fundamentals of drying processes

Types of dryers and their applications

Design and optimization of drying systems

Membrane Processes

Membrane separation principles

Types of membranes and modules

Applications in industry

Advanced Topics in Unit Operations

Process intensification

Novel separation techniques

Environmental and energy considerations

Process Simulation and Modeling

Introduction to simulation software (e.g., Aspen Plus, COMSOL)

Building and analyzing models of unit operations

Practical examples and case studies

Optimization and Troubleshooting

Techniques for process optimization

Common operational issues and solutions

Case studies of real-world troubleshooting

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

Process Engineering World

Questions and Answers

A: The rate of diffusion in gases is influenced by several factors including the concentration gradient, temperature, pressure, and the properties of the gases involved. According to Fick's law, the diffusion flux is proportional to the concentration gradient. Higher temperatures increase molecular motion, thus enhancing diffusion rates. Pressure can affect the gas density, which also impacts diffusion. Additionally, the molecular size and interactions between gas molecules play a significant role. For quantitative analysis, the Chapman-Enskog equation is used to estimate diffusion coefficients. For detailed information, refer to https://www.sciencedirect.com/topics/engineering/mass-transfer.

A: A distillation column separates components based on differences in their volatilities or boiling points. The mixture is heated to vaporize the more volatile component, which rises through the column. As the vapor ascends, it contacts descending liquid, facilitating mass and heat exchange. Components with lower boiling points concentrate in the vapor phase and are collected as the distillate, while those with higher boiling points condense and are removed as bottoms. The column efficiency depends on factors like the number of theoretical stages, reflux ratio, and tray or packing design. An excellent reference to understand distillation is Warren L. McCabe's 'Unit Operations of Chemical Engineering.' More info available at https://en.wikipedia.org/wiki/Distillation.

A: Heat transfer by conduction occurs through direct molecular collisions and energy transfer within a material without any movement of the material itself, such as heat flowing through a metal rod. Convection, on the other hand, involves heat transfer through the bulk motion of fluids (liquids or gases), where the fluid carries thermal energy as it moves. Convection can be natural (caused by buoyancy effects due to density differences) or forced (induced by external means like a pump or fan). Understanding these mechanisms helps in designing heat exchangers and thermal systems. More on this topic can be found at https://www.engineeringtoolbox.com/conduction-convection-radiation-d_430.html.

A: Unit Operations refer to the fundamental physical steps in any chemical engineering process, such as filtration, distillation, drying, evaporation, and crystallization. They are important because any complex chemical process can be broken down into these basic steps, allowing engineers to design, analyze, and optimize industrial systems efficiently. Understanding unit operations is crucial to developing scalable and efficient chemical processes. For more details, you can refer to Perry's Chemical Engineers' Handbook or visit https://en.wikipedia.org/wiki/Unit_operation.

A: Centrifugation is a separation technique that uses centrifugal force to accelerate the sedimentation of particles within a suspension. By spinning a sample at high speeds, denser particles are forced outward to the bottom of the centrifuge tube, separating from the liquid phase. This method is widely applied in chemical engineering to separate solids from liquids, clarify liquids, and in biochemical applications for separating cellular components. The separation efficiency depends on rotor speed, time, and particle size. For further reading, see https://www.britannica.com/science/centrifugation.

A: Absorption is a mass transfer process where a substance (the absorbate) penetrates into the bulk of another phase (the absorbent), like gas dissolving into a liquid. Adsorption involves the accumulation of molecules only on the surface of a solid or liquid, without entering the bulk phase, such as activated carbon capturing impurities on its surface. Both processes are used for separation and purification, but their mechanisms differ. Absorption involves solubility and diffusivity, while adsorption depends on surface area and chemical affinity. For more insights, see https://www.britannica.com/science/adsorption.

A: The flow of incompressible fluids in pipes is governed primarily by the Navier-Stokes equations, which describe momentum conservation, and the continuity equation for mass conservation. For practical engineering, these reduce to Bernoulli's equation for inviscid flow and the Darcy-Weisbach equation to calculate head loss due to friction. Engineers use these equations to design pipe networks, select pump sizes, and predict pressure drops. Moody charts are also commonly used to determine friction factors. For an in-depth explanation, check https://www.sciencedirect.com/topics/engineering/pipe-flow and https://www.engineeringtoolbox.com/pipe-pressure-loss-d_253.html.

A: Drying is the unit operation of removing moisture from solids by evaporation. It typically occurs in three stages: the initial warming period, the constant rate period, and the falling rate period. In the constant rate period, moisture evaporates from the surface at a constant rate while in the falling rate period, moisture removal becomes diffusion-limited as water evaporates from within the solid. Drying is critical in industries like pharmaceuticals, food, and chemicals to increase product shelf-life or prepare materials for further processing. Detailed physical models and drying kinetics can be found in 'Unit Operations in Food Processing' by K. S. Subrahmanyam. More info at https://www.ahrebs.com/blog/drying.

A: Pressure drop in packed columns refers to the loss of pressure as fluids flow through the packing material inside the column. It is caused by friction between the fluid and packing surfaces and the resistance to flow through the void spaces. Pressure drop is significant as it affects the hydraulic performance, energy consumption (pumping costs), and operational stability of processes like absorption and distillation. Excessive pressure drop can cause flooding or channeling in the column. Engineers use correlations such as the Ergun equation to estimate pressure drop in packed beds. A detailed explanation is available at https://www.cheresources.com/content/articles/pressuredroppackedbed.

More from Same Author

- Technical Courses

- Articles

5

5607

1

E-Learning

Unlimited access

Beginner

E-Learning

Unlimited access

Pre-recorded videos

5

1342

2

E-Learning

Unlimited access

Beginner

E-Learning

Unlimited access

Pre-recorded videos

5

1824

21

E-Learning

Unlimited access

Beginner

E-Learning

Unlimited access

Pre-recorded videos

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

4

4874

47

E-Learning

Unlimited access

Beginner

E-Learning

Unlimited access

Pre-recorded videos

2930

22

E-Learning

Unlimited access

Advanced

E-Learning

Unlimited access

Pre-recorded videos

2438

4

E-Learning

Unlimited access

Beginner

E-Learning

Unlimited access

Pre-recorded videos

More Training & Development option to expand your reach

- Technical courses

- Soft-skills courses

- Seminars

- Articles & Blogs

1711

6

Online

Live courses

December 31

160 Hrs

Advanced

Online

Live courses

Interacting with trainer

689

Online

Live courses

February 21

30 Hrs

Advanced

Online

Live courses

Interacting with trainer

4

256

1

Online

Live courses

February 28

2 Hrs

Beginner

Online

Live courses

Interacting with trainer